Fuel cell systems are a key technology for sustainable energy generation - and therefore also for climate-friendly mobility without harmful emissions. When hydrogen is used as a fuel, only water and exhaust air are produced as emissions from the silent electrochemical process together with the oxygen in the air. However, this process poses challenges. To enable the safe and efficiency-optimized operation of fuel cell stacks, Hengst offers high-performance filtration solutions. Developed as modular systems or customized modules, they make an effective contribution to the expansion of CO₂-neutral mobility. As an experienced specialist in filtration and fluid management, we are thus living up to our corporate vision of "purifying our planet".

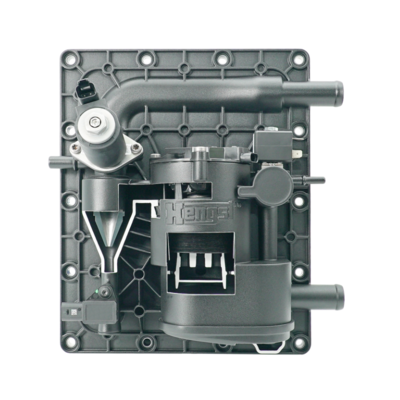

In fuel cell stacks, for example, the solubility of ionic components in the coolant circuit is problematic. This can lead to an increase in conductivity and to electrical short-circuit effects and power losses in the fuel cell. The Hengst Ion exchanger Blue.iox provides a remedy here and ensures safe operation of the Coolant with minimal electrical conductivity.

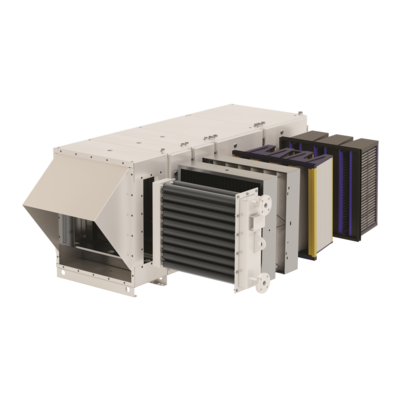

The use of a Blue.netic Cathode air filter specially developed for this application protects the central components of the fuel cell from harmful gases and particles. The particularly effective filtration of sulphur gases and ammonia prevents damage to the catalytic converter and membrane of the fuel cell.

Many fuel cells recycle unused anode gas in order to recover excess hydrogen. To do this, water (which is mixed with the excess hydrogen gas) must be removed. Hengst offers a compact water/gas separation system that uses a novel valve design to effectively purify the water and recycle the recovered hydrogen back into the anode gas stream.