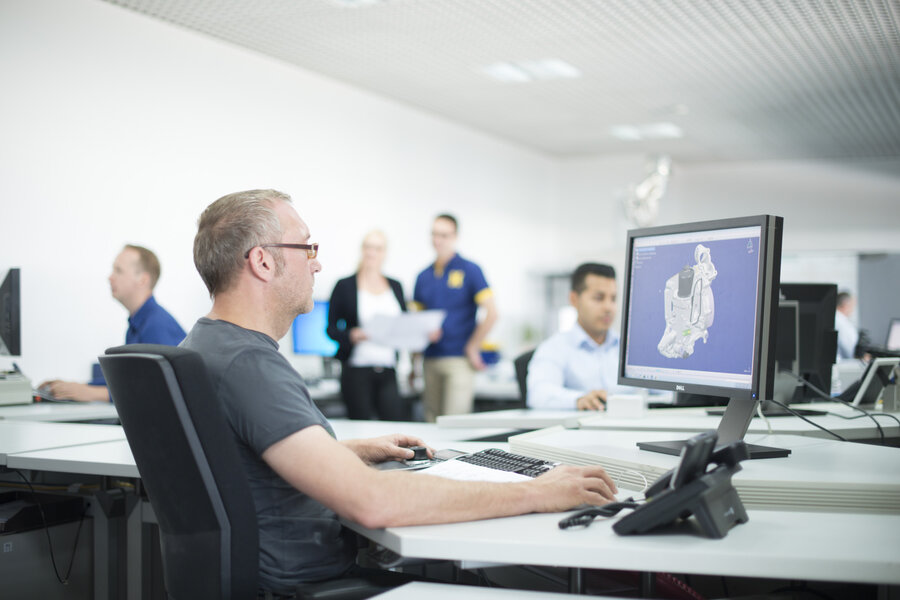

More than 300 employees work at Hengst to develop innovative filtration solutions. With sound training, the ability to think outside the box and a great deal of creativity, they meet the high demands of manufacturers - no matter how impossible they may seem at first glance. Our developers are supported by all common CAD programs and state-of-the-art test benches. In addition, the know-how of related departments, such as production, flows into our development work. A high level of material, testing and assessment expertise is therefore already ensured at Hengst during the development phase.

Test passed!

The fact that FMEA is written in capital letters at Hengst is not only for orthographic reasons, but is also an important tool in development to avoid errors in the initial phase. Computer simulations and extensive testing facilities from the test field to the engine test bench and the vibration test bench ensure that errors can be ruled out in all phases.

Luxury cars, commercial vehicles, vacuum cleaners or filter solutions for gas turbines

Be it a high-end luxury sedan, high-performance sports car, heavy-duty commercial vehicle, vacuum cleaner or Filter cartridges for the protection of gas turbines: The fact that we develop filtration solutions for all these applications demonstrates the breadth of our expertise in being able to develop the optimum solutions for all requirements.