The production of cement consumes large amounts of energy and is subject to strict emission controls to protect the environment. We advise you on how you can create and safeguard production capacities, reduce downtimes and contribute to reducing emissions with the right filtration solutions. Our Dust extraction filters are characterized by their long service life, energy efficiency, excellent cleanability and robust design. We will work with you to find the filter solution that will help you achieve your goals.

Air filtration for the cement production process

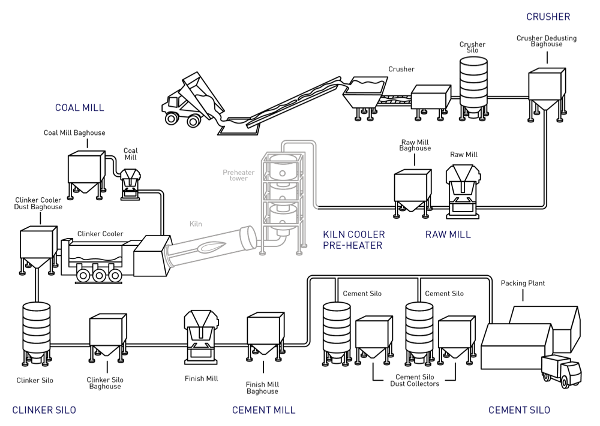

We offer Pleated bag filters, Filter cartridges and Flat cell filters for all important process steps in a cement plant that require air filtration. Our Air filters are tailored to the specific requirements of each process stage, from high temperature applications in the clinker cooler, to medium temperature requirements in raw and finish mills, to low temperature requirements in silos and bin vents, packing houses and loading stations, terminals and ready mix plants. Our Pleated bag filters are particularly efficient when it comes to coping with high dust loads and different types of dust.

Your benefits

Our filter portfolio includes a wide variety of Air filters. In cement production, our Pleated bag filters are ideal for the demanding conditions. Compared to filter bags, our Pleated bag filters are shorter and offer a larger filtration area. This results in several benefits for your production.

Create and secure production capacities

The larger filtration area of Pleated bag filters combined with a shorter length allows you to maximize air throughput or improve filtration efficiency. This allows you to release unused production potential or safeguard existing production capacity with future, stricter emission regulations. Thanks to the plug-and-play principle and our broad portfolio of Pleated bag filters, our filters can be easily retrofitted to any dust collector.

Reduce total cost of ownership (TCO)

Our Pleated bag filters are designed to minimize operating costs such as maintenance and energy costs, reducing the TCO over the lifetime of your operation. In many cases, this shortens the payback period for the filter purchase.

Optimize energy efficiency

Our Pleated bag filters use innovative surface filtration media. This results in a lower pressure drop. Surface filtration media allows for better cleaning and the pleating of the media increases the filtration area compared to a filter bag of the same length and diameter. This leads to a lower pressure drop of the Filter Elements and has a positive effect on energy consumption.

Improve the service life of Filter Elements

Benefit from longer filter service life and improved product safety thanks to the Weltech technology integrated into our Pleated bag filters. Compared to filter bags, the pleated media of Pleated bag filters reduces the length while maintaining the same filter surface area. This results in less abrasion and wear inside the filter housing and extends the service life of the filter.

Optimize maintenance

The lower abrasion reduces maintenance intervals and maintenance costs, while the star base design enables better cleaning.

Customized solutions

Use our technical expertise to tailor solutions to the exact requirements of your plant, ensuring optimum performance and compliance with industry norms and standards.

Your partner for air filtration

Hengst specializes in improving the performance of filtration systems throughout the cement manufacturing process with high quality products and services. Our mission is clear: to reduce emissions in cement plants and improve efficiency in production to make our planet a cleaner place.

From retrofitting existing plants to planning and commissioning new plants, Hengst is with you every step of the way. Our comprehensive range of services includes site visits, dust testing and innovative design solutions, such as 3D printing technology for first-fit testing.

Together with our global customer base, we have successfully optimized filtration in several cement plants.

For example, we were able to reduce emissions by 95 % in Portugal, increase capacity by 20 % in Croatia and quintuple the service life of filters in Switzerland.

MyAirfiltration.com

Simple filter purchase. Increase efficiency.

Discover the benefits of purchasing with myAirfiltration.com. On our platform, you can explore our complete range of Air filters, easily place orders and request customized filters with just a few clicks. Benefit from advanced filter options and a seamless connection with our team for all your needs.