Filtration Fuel Cells

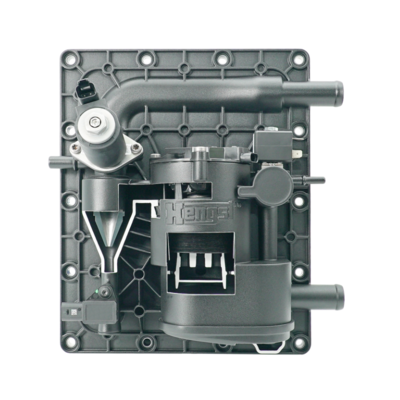

Cathode air filter system Blue.netic

Fuel cell air treatment system for stationary and maritime applications

Fuel cells can not only achieve climate protection targets in the marine and industrial sectors more quickly, but also reduce dependency on fossil fuels. With a technology kit for cathode air filtration, Hengst offers an efficient way to ensure the long-term performance of fuel cells. This applies in particular to applications in ships, stationary large and megawatt systems and electrolysers. The operating conditions here are often particularly adverse and the demands on reliability are high.

Protection against harmful gases and particles

The technology concept developed by Hengst offers free scalability of the filter surfaces and thus the Air flow through the filter system. If there is a higher demand, the individual filter stations can either be enlarged or several stages can be operated in parallel - Filter systems for fuel cells with an electrical output of several megawatts can also be easily implemented.

Overall, cathode air filtration is an important component of electrolysers in order to produce high-quality and reliable hydrogen and prevents contamination by salts and moisture in the fuel cell itself, which cause corrosion.

Benefits

Cathode air filter system Blue.netic – Your customer benefits at a glance:

Fuel cell gas filter offers effective protection for catalytic converter and membrane

Coordinated filter stages ensure maximum dust holding capacity and separation efficiency

Modular filtration and air treatment stages ensure easy adaptability

Developed for robust use in stationary and maritime applications

Easy servicing of Filter Elements

Application area from medium-sized systems to megawatt applications

Integration of measurement technology for filter monitoring possible

Details

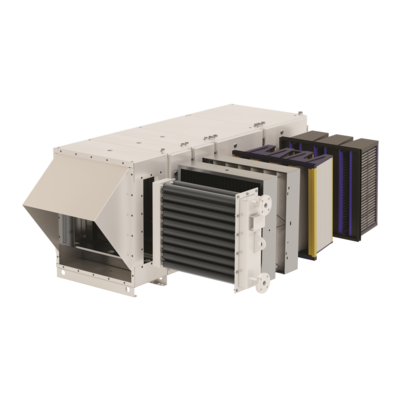

Modular design of the cathode air filter systems

The cathode air filter systems from Hengst always have a multi-layer structure. Each layer is optimized for a specific task so that the complete system offers reliable protection against all harmful particles and gases in the intake air when all filter stages work together. Thanks to a high degree of modularization, all requirements for different applications worldwide can be met from a uniform technology kit. This leads to the shortest development and application times, increases robustness and longevity through the use of tried and tested, coordinated components and makes the use of the components particularly economical over their lifetime. The range of applications covered by Hengst cathode air filters extends from small fuel cells and mobile systems in the on- and off-highway segment to large systems for stationary power generation and for ships.

The 5-stage air filter system for large stationary and maritime fuel cell systems shows an exemplary packaging of the filter stations in a compact housing. The individual elements can be easily removed and replaced for servicing. Instead of as a complete module, individual filter stages can also be accommodated in separate housings, for example for integration in confined installation spaces. OEMs also have the option of combining individual modules with existing filter stages to create their own cathode air filter system.

Downloads

2 MB