Oil Filtration

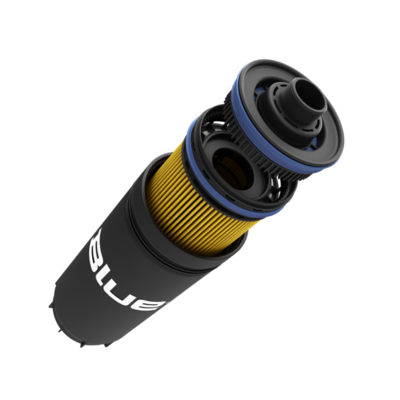

Oil filter system for electric axles

Integrated functions and robust performance for extreme conditions

The e-axle is an innovative solution for the electric drive of battery electric vehicles and hybrid applications. It combines the motor, axle and transmission into one compact unit, which reduces the complexity and costs of the drivetrain. E-axles require around a third of the installation space of conventional combustion engines.

The importance of a Transmission oil filter for the e-axle should not be underestimated. Modern e-axles require efficient lubrication to ensure reliable performance. A high-quality oil filter system ensures that the oil remains clean and the components are optimally lubricated. This is particularly important to extend the service life of the e-axle and maximize its efficiency. Clean oil prevents wear and protects against damage caused by contamination.

Hengst offers oil filter solutions for various requirements, including long-life oil filter inserts, compact Oil filter modules with multiple functions and specialized modules for separate oil circuits in electric motors and transmissions.

Benefits

Oil filter system for electric axles – Your customer benefits at a glance:

Space-saving: Numerous functions such as electric oil pump, Oil filter, temperature and other sensors, oil drain valve and cooling for the electric drives are combined in a compact installation space in the module.

Filter medium: The fully synthetic filter medium has been specially developed to ensure a long service life even with a limited filter surface. It can withstand high pressures and offers a long service interval.

Easy servicing: The patented Filter Elements have an integrated oil drain valve for clean and quick servicing.

Materials: In our own production facility, we manufacture the component from plastic, aluminum or as a hybrid module, depending on requirements. This flexibility enables us to offer customized solutions.

Robustness: The component is robust and reliable, even in extreme cold conditions and adverse environments.

Scalable: The system design allows easy scalability of the oil filter systems to cover a wide performance spectrum

Details

Customised solutions are offered for the different requirements of vehicle and e-axle manufacturers. These include oil filter inserts with fully synthetic filter media, which are designed for replacement intervals of up to six years or 800,000 kilometres. These filters are able to withstand temperatures from -40°C to 150°C.

There are also compact oil filter modules that combine several functions in one component. These modules contain an oil filter, a heat exchanger, an electric oil pump as well as valves, sensors and a thermostat. The housings of these modules are either made of plastic or die-cast.

We also offer oil filter modules that integrate additional functions in order to map the separate oil circuits for the electric motor and transmission in a single component. These modules also include oil filters suitable for both different cooling circuits with the different oils. But also a heat exchanger, a coolant control unit, an electric oil pump as well as valves, sensors and a thermostat.

Modern simulation technology is used to find the optimum component shape and ensure improved differential pressure behaviour.Thanks to leading system integration and a high level of vertical integration, including in-house plastic injection moulding and aluminium die-casting production, robust and reliable solutions are created that ensure smooth lubrication and withstand high pressures even under extreme conditions.

Hengst offers you innovative oil filter solutions for eAxles that impress with their high quality and reliability. With our expertise in system integration and our high level of vertical integration, we are able to develop customised solutions for your requirements.We look forward to hearing from you