Crankcase Ventilation for clean engine performance

Blue.tron active oil mist separator

Active Crankcase Ventilation for maximum efficiency and minimum emissions

New global emissions standards place high demands on engine development. Low-emission petrol and diesel engines with modern combustion processes require very good oil separation values for the crankcase air. The technological trend is therefore towards active ventilation. The Electrically driven disk separator Blue.tron is currently the most technologically advanced Crankcase Ventilation system. It offers highly efficient oil separation and active blow-by conveying for Crankcase Ventilation. The reduction of oil ingress into the engine's intake system enables a higher boost pressure level, which can be used to increase engine performance and efficiency.

According to EU legislation, the crankcase pressure must be below the ambient pressure in order to prevent exhaust gases from escaping from inside the engine. To meet this requirement, a Crankcase Ventilation system that does not restrict the flow from the crankcase into the engine's intake system is preferable. This ensures legal compliance and at the same time improves the engine's oil return from the turbocharger, valve stem seals and the oil separator itself. The Hengst Blue.tron even supports this flow.

Fine oil aerosols that occur in high-performance combustion engines can have a variety of negative effects. The best known effect is the coking of the turbocharger in diesel engines, which leads to a loss of engine performance and increased fuel consumption. Another negative consequence can be pre-ignition at low engine speeds caused by oil aerosols. Hengst Blue.tron filtrates these fine oil droplets to the highest degree and ensures continuous high-performance engine operation.

The Hengst Blue.tron electric drive is designed to maximize performance, control, efficiency and installation flexibility. Compared to a hydraulic drive, the speed possible with the electric drive is 50% higher and easier to control in order to adapt to different engine operating points and use as little drive energy as possible. The Blue.tron can be positioned anywhere in the engine compartment, eliminating the need for large hoses and connection cross-sections for the oil supply and return as required for hydraulic drive systems.

Benefits

Blue.tron active oil mist separator – Your customer benefits at a glance:

High engine efficiency, low emission values and emission stability over the entire product service life

Highly efficient aerosol particle separation up to 95% @ 0.3 µm, which protects the intake system from deposits, the engine from irregular combustion and the environment from pollution

Active blowby delivery, which results in crankcase pressure below ambient pressure, ensures legal compliance, proper turbocharger oil return and the possibility of round-the-clock engine operation

ECU interface via LIN bus enables on-board diagnostics (OBD) and speed control of the disk separator to adjust cleaning performance, crankcase pressure and energy consumption

Easy installation for existing and new motors thanks to electric drive, great flexibility in design and connections and pre-installed pressure control valve referenced to ambient pressure

No fundamental changes to the motor hardware or software necessary

Fit for future combustion processes with the use of low-carb fuels, water injection, EGR utilization and Miller cycles

Enables the use of a dilution solution for the crankcase atmosphere at all engine operating points - to protect the environment and the engine itself

Add-ons

Adaptation

Connections

Fastening

Pressure control

Sizes

Dilution system

References

Blue.tron - active Crankcase Ventilation High-volume technology in hyper cars

The Blue.tron 160 guarantees maximum filtration efficiency with active venting of the dry sump tank. The differential pressure-optimized design with external pressure control enables the lowest pressure levels. The control of the Blue.tron via a LIN protocol ensures demand-oriented operation.

Blue.tron - active Crankcase Ventilation for BMW 6-cylinder engines

Active Crankcase Ventilation offers highly efficient oil separation and active blow-by promotion for crankcase ventilation. The reduction of oil ingress into the engine's intake system enables a higher boost pressure level, which can be used to increase engine performance and efficiency.

Blue.tron - active Crankcase Ventilation High-volume technology in hyper cars

Two Blue.trons size 240 guarantee the cleaning of the blowby of a 1100 kW genset through maximum filtration efficiency with active venting of the dry sump tank. The pressure in the dry sump tank is controlled via two ambient pressure-referenced diaphragm valves.

Blue.tron - active Crankcase Ventilation for 4-cylinder petrol engines from VW

The electrically driven disk separator enables the highest degree of separation for liquid components in the blowby. At the same time, active blowby conveying ensures compliance with the approval requirements with regard to crankcase pressure. The compact module is bolted directly to the engine block.

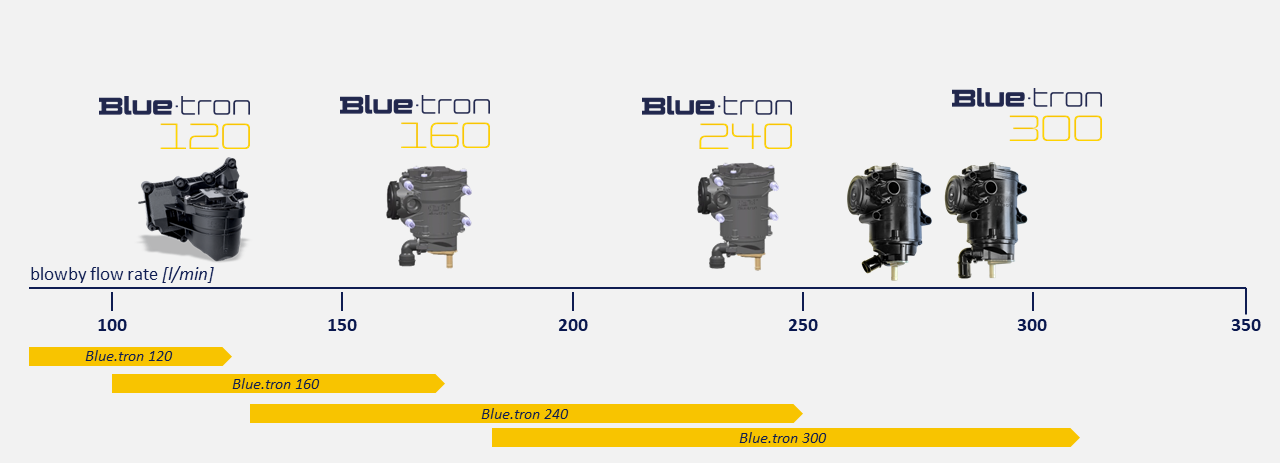

Blue.tron construction kit

Hengst Filtration offers both basic sizes and customized sizes of disc separators.