Filters ensure high system availability in machines and systems with liquid operating media. Hengst has completely redesigned the filter material as part of a holistic filtration concept. The development focus was on increasing the dirt holding capacity compared to the previous design. This extends the replacement intervals and reduces labor, material and disposal costs.

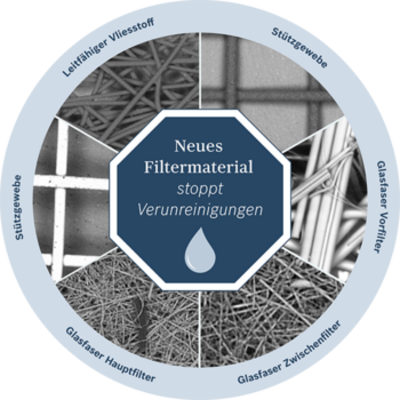

6 layers, maximum protection

The Filter Elements consists of a 6-layer material combination, the core of which is made up of asymmetrically arranged filter layers of inorganic glass fiber paper. The optimum coordination

of the individual filter layers achieves a high retention rate and dirt storage capacity with low pressure loss. This increase in performance is achieved by three effective

In the pleated state, the filter material is laid around the support tube in a cylindrical shape as a filter mat and is connected at the ends with the two end caps.

The end faces are glued to the two end discs to form a liquid-tight seal, as is the longitudinal seam of the Filter mats themselves.

1. supporting fabric

Support fabric is used to fix the filter material

on the upstream side

2. Pre-filter

Micro-glass pre-filter layer to relieve the downstream

Micro-glass pre-filter layer to relieve the downstream

intermediate and main filter in terms of dirt absorption

3. Intermediate filter

Micro glass intermediate filter layer to relieve

of the downstream main filter

4. Main filter

Micro glass main filter for fine particle filtration and

Micro glass main filter for fine particle filtration and

ensuring the nominal filter fineness

5. Electrically conductive fleece

Protective fleece - antistatic, reduces the risk of electrostatic

electrostatic charges and discharges in the filter system

6. Stainless steel support mesh

Support mesh is used to fix the filter material

on the downstream side

Filter Elements with PURE POWER now remove up to 50 % more particles, with a comparable retention rate and low differential pressure. All Filter Elements are equipped with an electrically conductive fleece as standard, which ensures a charge exchange between the oil and filter material. This reduces the risk of electrostatic charges and discharges in the filter.

Developed to absorb the five most important types of soiling

Innovation for better filtration: Several filter material components have been individually matched and further developed to bind and remove the five most common types of contamination in the hydraulic fluid in order to achieve optimum protection.

- Basic contaminants

- Abrasion

- External particle ingress

- Varnish

- Insoluble reaction products

Hengst Filtration works with the latest technologies to continuously improve every aspect of hydraulic filtration.

Up to 50 % higher dirt pick-up saves time and reduces costs

The latest glass fiber material within a 6-layer material design gives the latest generation of Filter Elements with PURE POWER two decisive benefits:

- Up to 50 % higher dirt holding capacity - the more dirt is held by a filter, the longer the service life and shorter the replacement intervals

- Reliable filtration efficiency based on 3-layer glass fiber technology

These benefits help to reduce your operating costs and extend service life.

Reduce your TCO

One of the factors that influences the total cost of ownership of a hydraulic system is downtime. Here, the improved design of the new Filter Elements with Pure Power has a direct influence on both factors, downtime and operating costs:

- Reduces maintenance costs by extending downtimes and therefore replacement intervals

- Protects the hydraulic system for longer and from more contamination

Do you still have questions? We will be happy to help you

PURE POWER product brochure

815 KB