Filtration Fuel Cells

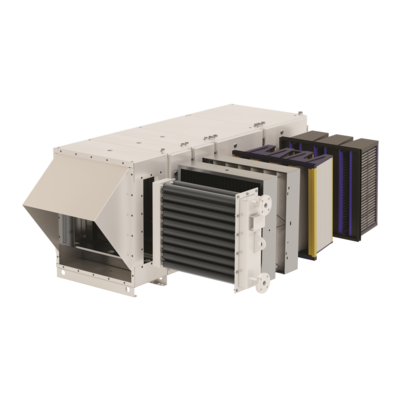

Cathode air filter Blue.netic

Effective air purification for the long-term performance of fuel cells

Fuel cells require a constant supply of clean air to function properly. Air compressors/blowers are used to force air into the fuel cell stack - where the cell uses oxygen from the air to enable the reaction in the cathode. This means that there are special air supply requirements for fuel cells. To ensure a long service life and high performance, the intake air must be very effectively cleaned of particles in the outside air.

Protection against harmful gases and particles

In addition, pollutants such as nitrogen oxides (NOx), ammonia (NH3) and sulphur oxide (SO2) can cause unwanted deposits in the fuel cell and damage it. We use a specially formulated carbon layer to trap these and other harmful gases. Hengst's cathode air filter systems always have a multi-layer structure. Each layer is optimized for a specific task so that the complete system offers reliable protection against all harmful particles and gases in the intake air when all filter stages work together.

Benefits

Cathode air filter Blue.netic – Your customer benefits at a glance:

Perfect protection for NT-PEM fuel cells

High-performance gas filter protects against gases harmful to fuel cells (SO2, NH3, NOx, VOCs)

Highest adsorption of ammonia (NH3)

SO2 optimized filter available

Particle separation efficiency >98 % @0.2 µm

Details

Modular design of the cathode air filter systems

The cathode air filter systems from Hengst always have a multi-layer structure. Each layer is optimized for a specific task so that the complete system offers reliable protection against all harmful particles and gases in the intake air when all filter stages work together. Thanks to a high degree of modularization, all requirements for different applications worldwide can be met from a uniform technology kit. This leads to the shortest development and application times, increases robustness and longevity through the use of tried and tested, coordinated components and makes the use of the components particularly economical over their lifetime. The range of applications covered by Hengst cathode air filters extends from small fuel cells and mobile systems in the on- and off-highway segment to large systems for stationary power generation and for ships.