purifying our planet

Our vision

Sustainable

We make the planet a purer place with our products. We also take this journey as cleanly as possible.

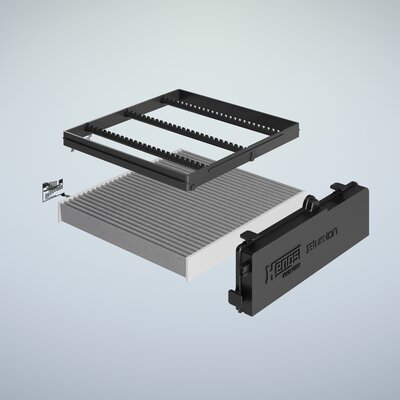

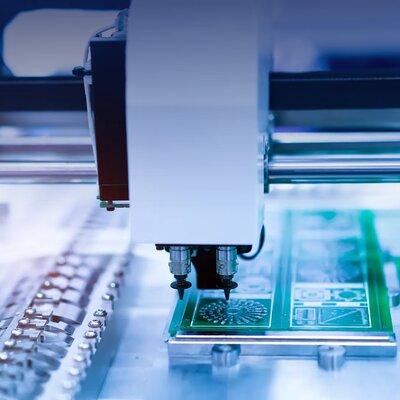

Innovative

We develop the filtration solutions of the future. For our customers and for society.

Efficient

Our focus is on energy efficiency. This protects the environment and saves costs.